As a leading automotive battery manufacturer in India, Sarex is committed to not only producing high-quality batteries but also promoting safety and proper maintenance practices.

In this blog, we will explore essential tips to ensure the safe handling and maintenance of automotive batteries. We’ll be focusing on four major points that you need to take care while handling an automotive battery.

1.Safety Precautions:

When dealing with automotive batteries, safety should always be a top priority. Here are some essential safety precautions to follow:

-Protective Gear:

Wear protective gloves, safety glasses and clothing that covers your skin to prevent acid burns or electric shock.

-Ventilation:

While working with an automotive battery make sure that you work in a well-ventilated area to avoid inhaling harmful gases released by the battery.

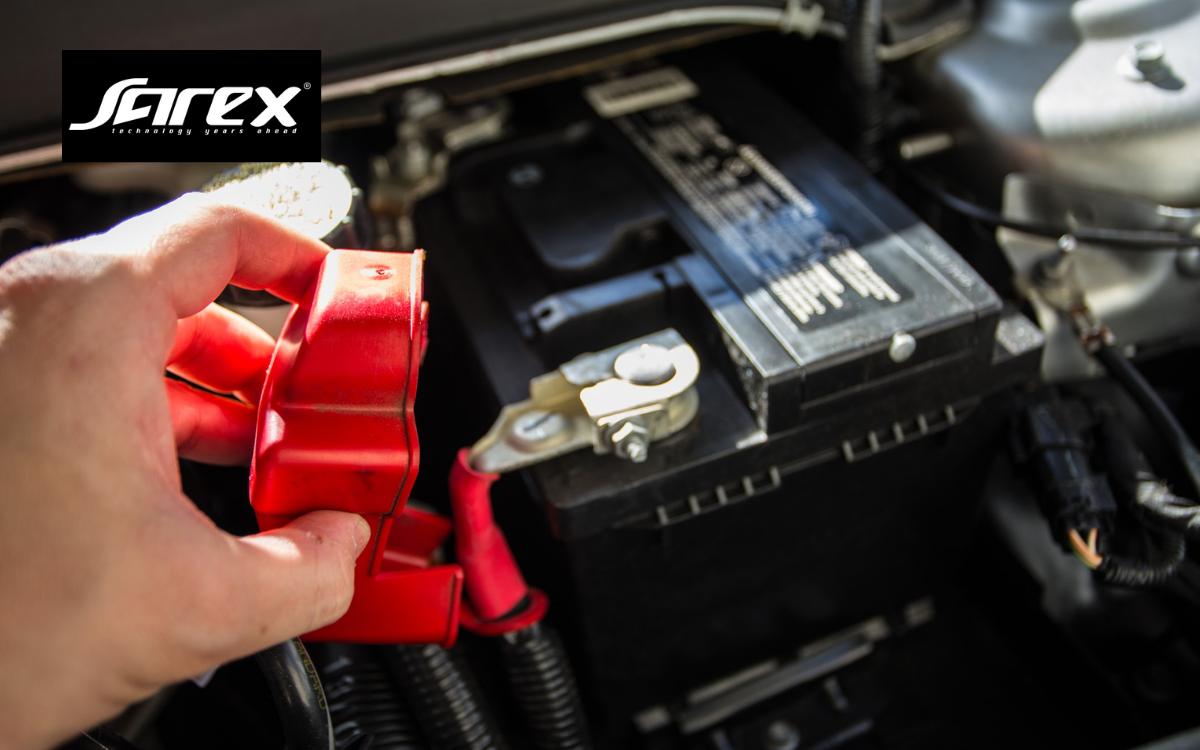

-Disconnecting the Battery:

Before performing any maintenance or repairs, ensure that the vehicle’s ignition is off and the battery cables are disconnected.

-Proper Lifting Technique:

Automotive batteries are too heavy and improper lifting can cause you strain or injury so make sure that you lift a battery with care, using proper lifting techniques and equipment.

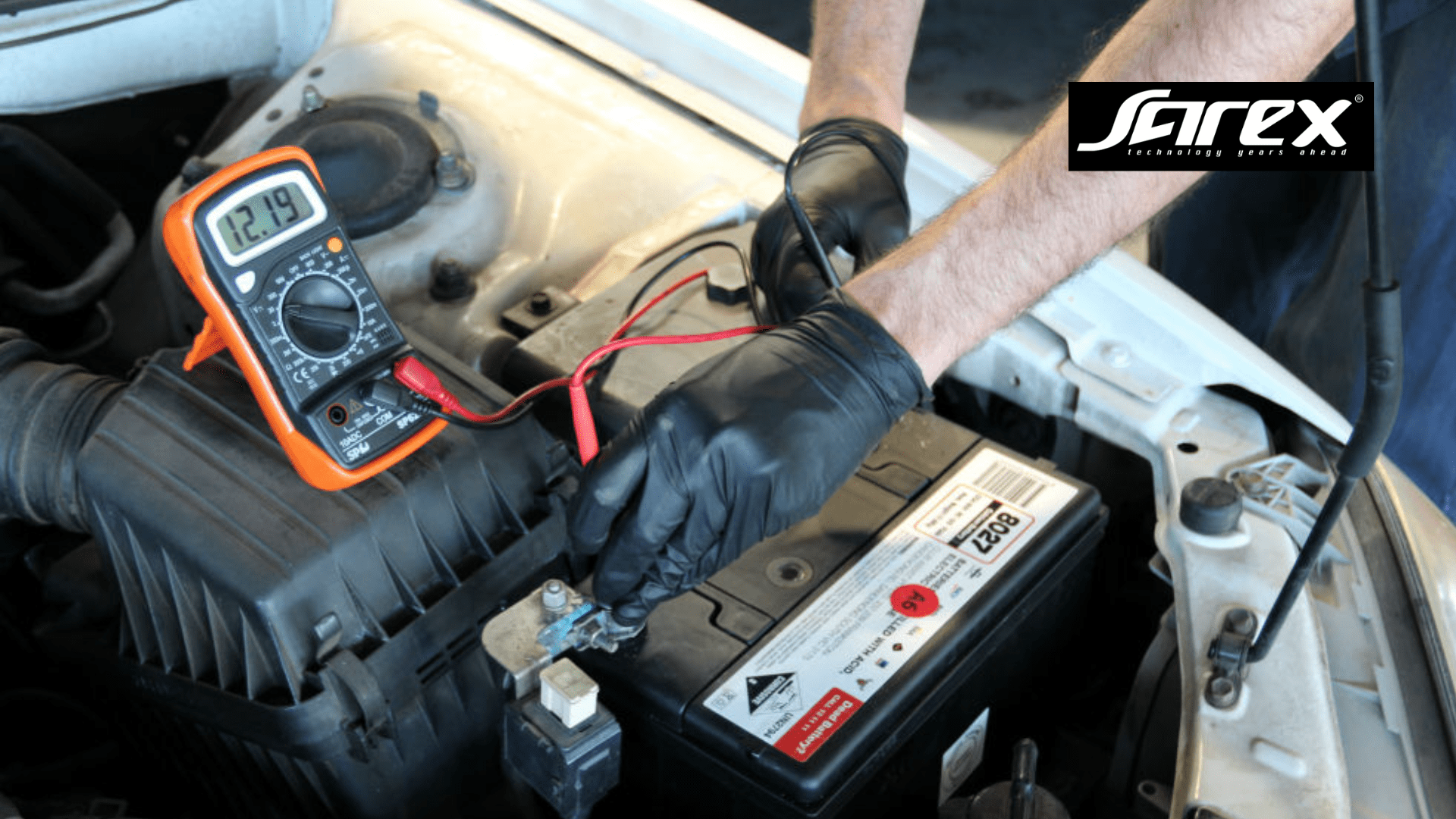

2.Regular Inspection:

Regular inspection of your automotive battery is crucial to detect any potential issues early on. While inspecting or maintaining an automotive battery you should follow these guidelines:

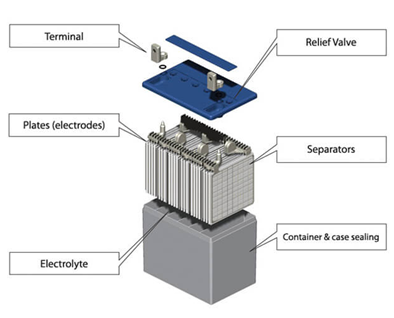

-Check Battery Terminals:

Ensure the terminals are clean, tight and free from corrosion. Clean them with a mixture of baking soda and water if necessary.

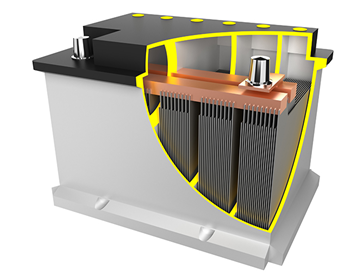

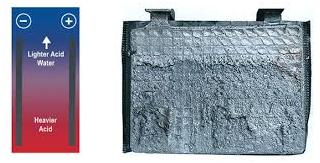

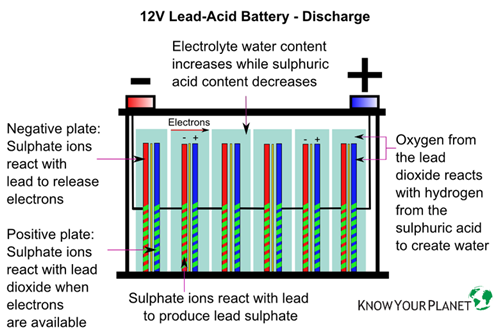

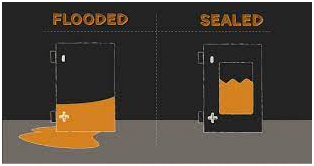

-Monitor Fluid Levels:

For batteries with removable caps, check the fluid levels regularly and add distilled water if needed and also make sure that you overfill the battery.

-Inspect Casing:

Look for any cracks, bulges or leaks in the battery casing. If you notice any damage, replace the battery immediately.

-Check Cables and Connections:

Inspect the battery cables and connections for any signs of wear or corrosion. Replace or clean as necessary.

3.Charging and Jump-Starting:

Improper charging or jump-starting can pose risks to both the battery and the person handling it. So, ensure your and batteries’ safety, follow these guidelines:

-Use the Right Charger:

Always use a charger specifically designed for automotive batteries and follow the manufacturer’s instructions.

-Avoid Overcharging:

Overcharging a battery can damage the battery so make sure that you do not leave the battery on continuous charge and disconnect it once it is fully charged.

-Correct Jump-Starting Procedure:

When jump-starting a vehicle, connect the positive (+) and negative (-) cables in the correct order to prevent sparks and potential damage to the battery.

-Seek Professional Help:

If you are unsure about jump-starting or charging procedures, it is best to consult a professional automotive technician.

4.Proper Storage:

Proper storage of automotive batteries is essential, especially when they are not in use for an extended period. Follow these storage tips:

-Clean and Disconnect:

Clean the battery terminals, disconnect the cables and store the battery in a cool and dry place.

-Charge Periodically:

If you are storing a battery for an extended period make sure that you charge it periodically to prevent it from getting damaged by self-discharge.

-Avoid Extreme Temperatures:

Store batteries away from extreme heat or cold, as it can impact their performance and shorten their lifespan.

-Follow Manufacturer Guidelines:

Always refer to the manufacturer’s instructions for specific storage recommendations.

Conclusion:

Sarex, a leading automotive battery manufacturer in India, provides tips for safe handling and maintenance. The blog covers important points: priorities safety precautions, conduct regular inspections, follow proper charging and jump-starting procedures and store batteries correctly. Tips include wearing protective gear, checking terminals and fluid levels, using the right charger and following manufacturer guidelines.