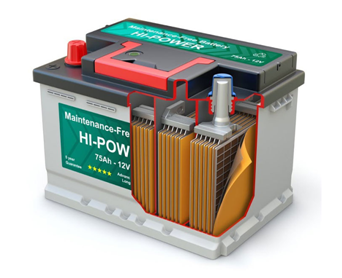

Every type of battery has its own pros and cons and choosing the right inverter battery depends on many reasons. With so many types of batteries available around us, we might be a little perplexed as to which type of battery we should go with. In this blog, we are going to compare tubular and flat plate batteries and evaluate their benefits and disadvantages. This way you can make an informed choice about your inverter battery.

Tubular battery vs flat plate inverter battery

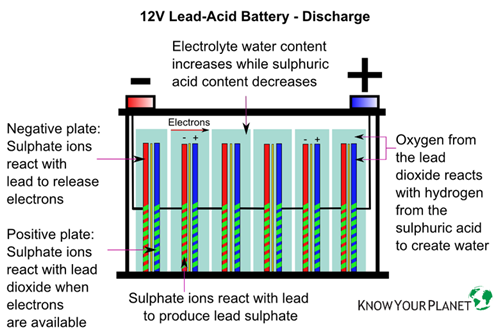

In the following section we are going to underline the difference between tubular and flat plate lead acid batteries in terms of the design, maintenance etc.

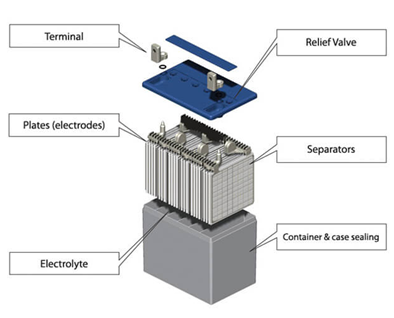

1. Design

a)Tubular Batteries:

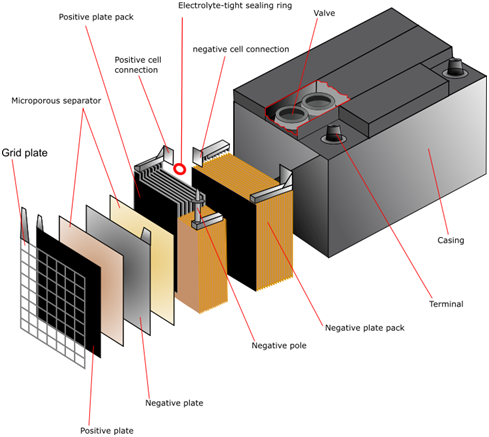

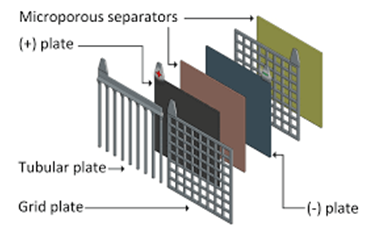

Tubular batteries have a unique design, in which the positive plate of the battery is different from the negative plate. The positive plate is made up of cylindrical shaped tubular structures which store the active material. This design helps to prevent the shedding of the active material leading to a long life.

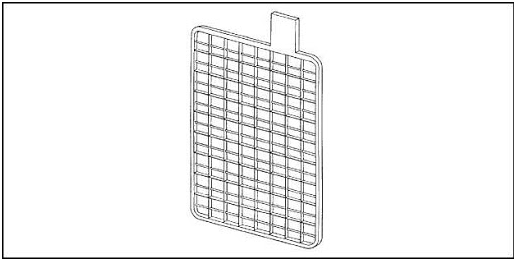

b)Flat-Plate Batteries:

In flat-plate batteries, both the plates are flat, which gives them their name flat. Here the active material is pasted on the surface of the rectangular grids. The active material in these batteries get shed over the period of time and thus leading to a drop in the performance of the battery.

2. Application:

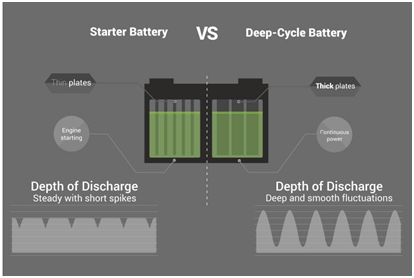

Tubular Batteries:

Deep cycling and long-term reliability applications require tubular batteries, such as inverter, traction and solar applications. Here the batteries need to supply power for a longer duration where the batteries will undergo regular charging and discharging cycles. Tubular batteries suit well for such applications.

Flat-Plate Batteries:

Being versatile, flat-plate batteries find applications in a wide range of applications, such as automotive starting batteries, uninterruptible power supplies (UPS), and general-purpose backup power.

3.Cycle Life:

Tubular Batteries:

Tubular batteries have longer life cycle due to their improved efficiency

known for their high cycle life. They can withstand a greater number of charge and discharge cycles compared to flat-plate batteries. Many inverter battery manufacturers offer reliable tubular batteries as a popular choice for powering inverters and uninterruptible power supply (UPS) systems.

Flat-Plate Batteries:

Flat-plate batteries offer reliable power but have a lower cycle life compared to tubular batteries. As they are not as robust & durable like tubular batteries, they are better suited for applications other than deep cycling.

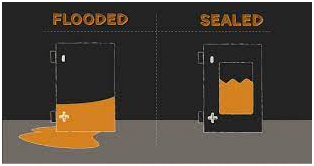

4. Maintenance:

Tubular Batteries:

When it comes to maintenance, owning a low maintenance battery gives peace of mind. With their robust construction, tubular batteries have less maintenance requirements and do not need to be topped frequently with water.

Flat-Plate Batteries:

Flat-plate batteries do require more frequent maintenance, including topping up with distilled water on a regular basis.

6. Cost:

Tubular Batteries:

Due to their varied advantages, tubular batteries sit typically at the expensive side. But their longer lifespan and cost savings in the long term make them more cost economical.

Flat-Plate Batteries:

Flat-plate batteries generally cost less and are budget-friendly too.

But due to frequent replacements, their long term costs increase.

Summary:

Selecting the right battery for your specific needs is a very crucial choice.

Hence knowing the difference between the types of batteries helps you to make an informed decision. So keep these points in mind and choose the best battery for your needs.

Sarex is a leading inverter battery manufacturer well known for its high-quality batteries. Our inverter batteries ensure uninterrupted power supply during electricity outages. We are trusted for our commitment to delivering efficient and long-lasting solutions, making them a preferred amongst the customers.